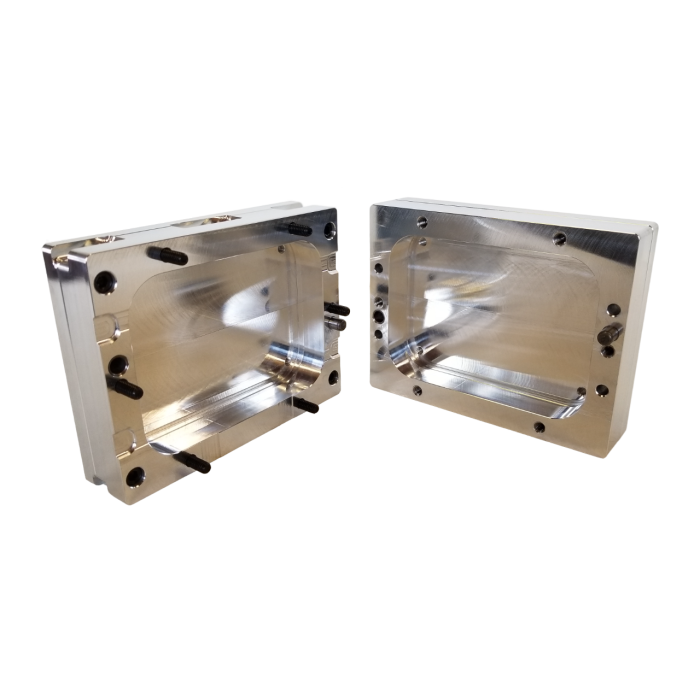

Injection Mold Frame With Integral Clamping

Aluminum frame for 3D printed injection molds.

Aluminum injection mold frame for 3D printed, cast resin, or CNC machined injection mold inserts. This frame has extra height and depth to take advantage of large capacity prototyping injection molding machines like the Buster Beagle 3D model MK3. When the integral clamping bolts are used, this frame can provide clamping force without an external vise.

Features

- Can be used in vertical or horizontal configuration without external vise.

- Integral clamping bolts can provide up to 10,000 lbs of force to reduce mold flash.

- Clamping bolts can be removed when the injection molding machine provides adequate clamping force.

- Pry slots make separating the mold halves easier for large molded items.

- Machined from 6061 aluminum.

- Includes one set of insert bolt caps.

Dimensions

| Model | Outer Dimensions | Cavity Dimensions |

| MFC505030 | 4.98" x 4.98" x 2.92" (126.5mm x 126.5mm x 74.2mm) | 3.75" x 3.75" x 1.96" (95.3mm x 95.3mm x 49.7mm) |

| MFC505040 | 4.98" x 4.98" x 3.92" (126.5mm x 126.5mm x 99.6mm) | 3.75" x 3.75" x 2.96" (95.3mm x 95.3mm x 75.2mm) |

| MFC655030 | 6.48" x 4.98" x 2.92" (164.6mm x 126.5mm x 74.2mm) | 5.25" x 3.75" x 1.96" (133.3mm x 95.3mm x 49.7mm) |

| MFC655040 | 6.48" x 4.98" x 3.92" (164.6mm x 126.5mm x 99.6mm) | 5.25" x 3.75" x 2.96" (133.3mm x 95.3mm x 75.2mm) |

| MFC808045 | 7.96" x 7.96" x 4.42" (202.2mm x 202.2mm x 112.3mm) | 6.0" x 6.0" x 2.96" (152.4mm x 152.4mm x 75.2mm) |

More Information

Mold Inserts

For low volume prototyping, mold inserts can be 3D printed on SLA / MSLA printers using high temperature resins such as Siraya Tech Sculpt or Sculpt Ultra.

CNC machined aluminum inserts can be used for higher volume molding.

Mold inserts are typically fastened into the mold frame using the included 1/4-20 cap screws. This makes it easy to adjust the height of the mold inserts to account for 3D printing variations. The back of the mold insert can be sanded, or paper shims can be added to achieve the desired insert height in the mold frame. Inserts can also be held in the frame using the retention channel at the back of each cavity. This eliminates the need for cap screws and allows the use of the entire cavity volume, but requires a more precise 3D print to achieve the proper height.

Notes for Specific Machines

| Molding Machine | Typical Sprue | Notes |

| Buster Beagle MK3 | 3/8" spherical | This mold frame is taller than the Buster Beagle 3D mold frame, so the nozzle height may need to be adjusted. |

| LNS Model 150A, 300A | 1/4" diameter straight sprue hole with chamfered outer edge | |

| Medium Machinery | Flat outer surface around sprue hole | |

| Morgan Press G-55T, G-100T, G-125T | 1/2" spherical |

The minimum mold thickness between platens is 5", so a spacer is required. We offer a mold spacer here. Clamping bolts are typically not used when injecting through the A end plate. The standard mold insert bolt holes on the A end plate of the 6.5" x 5" frame size interfere with the attachment bolt holes in the upper platen of the Morgan Press. This prevents the frame from being attached to the platen for semi-automatic operation. The insert bolt delete option allows the user to relocate the bolt holes, or use the insert retention channel and still mount the frame to the upper platen. |

Other Notes

Aluminum spacers are sold separately to decrease the cavity depth by 1/2" on one or both halves of the mold to save resin on shallower mold inserts.

A version of this mold frame with an ejector plate and riser is available here.

Looking for a different size of mold frame? Let us know, we may be able to add a size that meets your needs.

Drawings and Models

| SKU | SYN-MFC |

|---|---|

| Shipping Weight (LBS) | 8.000000 |

| Country of Manufacture | United States |

| Manufacturer | Syncorda |

| Manufacturer Part Number | MFC |

-

Injection Mold Frame With Ejector and Integral ClampingAs low as $364.00

Injection Mold Frame With Ejector and Integral ClampingAs low as $364.00